2009 was an amazing year for me as far as riding was concerned. I logged a little over 11,000 miles, met many new people and rode the FZ in some amazing places! With the miles adding up on the bike it was time to spend some $$ and time on her and get her back in tip-top shape for 2010.

2010, a new year with some new parts ready to have miles of adventures put on them. Since the cold weather has set in I have been busy working on getting a few things done to the FZ to prepare for pulling the trailer as well a little maintenance and upkeep.

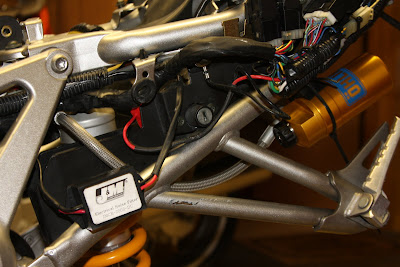

In order to prep the bike for pulling the trailer the following items were added: Ohlin’s rear shock, 0.85 N/mm fork springs (Ohlin’s), RaceTech Gold Valve Emulators, Stator Rewind, Acumen Digital Voltage Meter/Gear Indicator and added a hook up for the trailer lights.

In addition, I replaced the stock head bearings with All Ballz tapered roller bearings, cleaned and re greased the swing arm bearings, replaced the chain and sprockets, checked the tolerances in the valve train and rewired the air horn.

The work began the day I came home from Charlotte on winter break. With Dads current un-employment he was very eager to lend a hand and spin a few wrenches. So after cleaning up the shop and bit, the tunes were turned up and the bike started to come apart piece by piece.

Due to some communication errors, winter weather and the holidays , the project took a bit longer to complete than expected. However it did end being completed and I have the bike back in Charlotte now, ready to be ridden.

In order to have lights on the trailer, though for some silly reason they are not required by law in North Carolina, I needed to solder in a connection. For this project I chose a square 6 pin connector that way I would have the option to have a constant 12v power source on the trailer if needed.

On the FZ the harness for the tail lights, signals, ect. is located behind the left side pod on the bike. I had already spliced into the taillight wire to power the J&M intercom there and it has proven to be a good location for constant power with minimal noise. Once all the wires were located and there voltages determine I began cutting and soldering in the trailer light harness.

Once the chain was off I laid it flat on the floor and pushed the ends of the chain towards each other to see how much it would bend. This was the end result.

Yup it was toast...

I have been playing with the adjustment on the shock for a little bit now and I believe I have right about where I want it. It is so nice to be able to fine tune the shock now for my riding style. If only Yamaha would have included an adjustable shock on the bike from the factory.

Another item on the to-do list was to check the valves to see if they needed adjustment. The bike has over 30,000 miles on it now and to my knowledge they have never been checked. So we took the bike to do a friends shop in Albemarle, NC to see how they were. This motor will spin up over 12,000 RPMs and after 30,000 miles of riding they were all still very tight. No need for adjustments this round!

After riding the bike with the new gearing, I must say I wish Yamaha would have geared it this way from the factory. The RPMs are a much better range for riding the corners aggressively at a moderate speed. The bike accelerates a little faster now, but nothing crazy and its like a freaking tractor in first gear. You can just let the clutch out with no throttle to get it moving now.

I have never pulled a set of forks apart as we have always had a guy in Salisbury, NC do the work on our dirt bikes. (Bruce's Suspension) These forks are much simpler than those on my dirt bikes and unfortunately Bruce was recovering from a hip replacement. So with my lack of time available I decided that Dad and I should do the work ourselves. I wasn't aware that Dad was very familiar with these type of forks and after talking with Dad one evening we decided that we could tackle this one on our own.

Using a 5/16" drill bit a drill press at Timmy's shop we successfully open up the damping rod...

Below you can see where the emulator sits on the damping rod. It is then secured by the spring which rests on top of the emulator.

Next in line were the head bearings. Yamaha's factory ball bearing did not seal very well and ultimately rusted after a year or so in use. These bearings were replaced with tapered rollers made by All Ballz. It took a little work to get the old races out and the new ones in, especially on the lower side. In addition we had to get Alan to remove the old race from the steering stem and press the new one on.

Now that the bike is done, it is time to work on the trailer. I have made a contact with a guy in Salisbury that will be welding the trailer. Once some modeling changes are made and the design is checked with a FEA program, building will start. (Early March)

In addition to the trailer build up I have been thinking and talking a lot with Dad about rides for this coming year. For the past couple years we always start talking about what we want to accomplish in the year ahead.

After last years ride to West Virgina, I have become extremely fascinated with that area and look forward to making another trip up that way. I would like to spend more time at the Green Bank National Radio Observatory, eat another 12.00 banana split at the Green brier and would like to spend some more time riding through coal country.

Another goal is to cross the Mississippi River. I have been wanting to do this for sometime now and I am about bound and determined to do it this year. Mom has talked about going to North Dakota for my graduation ride for some time now. Realizing that this might not be an option, I have really started looking towards going to New Orleans. Ride through Nashville on the way there, cross the Mississippi and then go see what New Orleans has to offer.

A must do this year is to join an elite club known as the Iron Butt Association (IBA) to join this a rider must log over 1000 miles in 24 hours which is known as the SS1000. There are other goals that can be accomplished once in the association, but the SS1000 in the entry level. Dad and I have talked about this for a could years know and after plans were changed last year, we are bound and determined to do it this year!

On the FZ6 forum there are talks of having another Deals Gap ride around the first of August which I will try to attend. For the past few years I have made one trip up to Robbinsville, NC each season. I hope to continue this pattern and hopefully start making the trip more often.

As far as the MTF is concern there is a ride going on somewhere in The Smokies', however it is over Labor Day weekend. Not 100% sure on riding that area at that time as traffic will be a bit heavy and I tend to get frustrated when stuck behind slow traffic on fun roads...

But either way, plans are to ride and to ride alot. Once the last semester of my college career is over I will begin the job hunt and really my riding will depend on how that goes. So we shall see.